CNC Precision Machining

Digital-Driven Precision Machining Capability Overview

By integrating advanced CNC equipment with precision machining expertise, Huang Liang Precision has established a digitally driven CNC precision machining framework. Our capabilities are designed to support modern manufacturing requirements, helping customers maintain stable quality and consistent machining performance across diverse production conditions.

Digital CNC Precision and Diverse Machining Applications

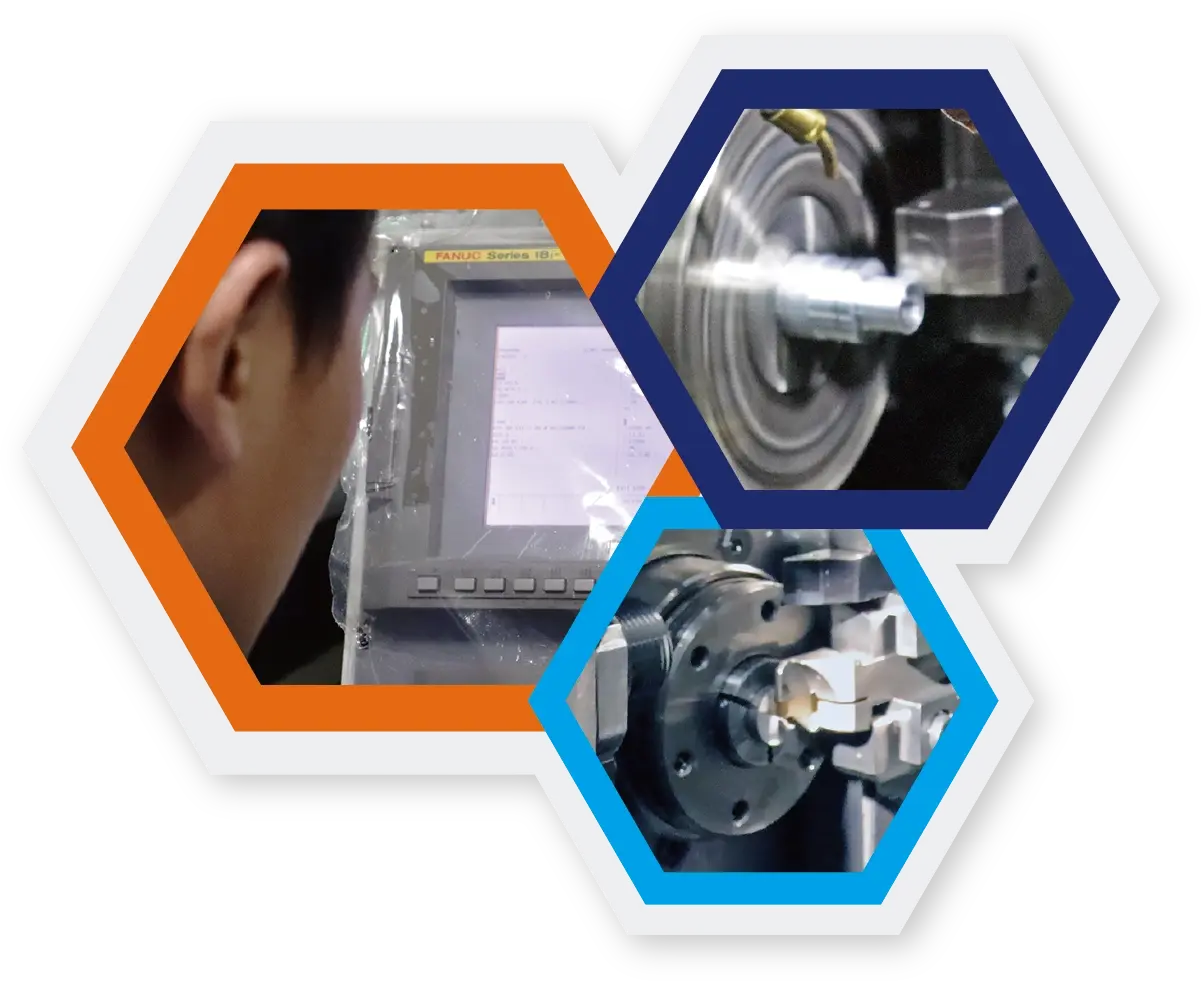

With over 30 years of experience in precision machining, we continuously strengthen the integration of CNC technology and smart manufacturing systems. Through machine connectivity and digital monitoring, machining conditions are tracked in real time to ensure process stability and reduce deviation risks. This framework supports a wide range of machining needs, from prototype development to various production scales.

CNC Turning Capability

We provide high-precision CNC turning capabilities to meet machining requirements for components of different geometries and materials. Supported by stable machining conditions and digital monitoring, our turning processes ensure consistent quality and meet fundamental requirements for dimensional accuracy and repeatability.

CNC Milling Capability

Our CNC milling capabilities support multi-axis machining and complex structural components. Through flexible process planning and controlled machining conditions, we enable accurate structural machining for a wide range of parts while maintaining overall dimensional precision and quality compliance.

Multi-Material Precision Machining Support

We machine a wide range of materials, including aluminum, stainless steel, carbon steel, brass, and engineering plastics such as PEEK and PTFE. Machining parameters and strategies are adjusted according to material characteristics to ensure stable material performance throughout the machining process and to support diverse application requirements.

High-Precision Micron-Level Machining

By utilizing advanced CNC machines and digital process monitoring, we establish stable high-precision machining capabilities for components with strict dimensional requirements. Our technical team optimizes machining conditions based on product characteristics to ensure process stability and consistent finished-part quality.

Automated Equipment and Flexible Production Configuration

We deploy flexible CNC equipment configurations and production line planning to support batch switching and different production volumes. Through automation and integrated process design, overall manufacturing efficiency is enhanced while maintaining stable quality and delivery performance.

Process Control and Stable Quality Management

Process monitoring and quality management mechanisms are implemented to ensure repeatability and stability throughout machining operations. Standardized machining modules and quality control practices help reduce process variation and improve overall manufacturing consistency and reliability.

Process Data Integration and Production Visualization

By integrating process data and production information, we improve manufacturing visibility and management efficiency. Digital data integration supports process optimization and decision-making, strengthening the stability of the overall manufacturing system.

Integrated Post-Processing and Value-Added Services

We offer integrated post-processing options such as sandblasting, anodizing, laser marking, and surface coatings. Through coordinated process integration, we provide comprehensive machining support that balances functional requirements with surface quality and application flexibility.

Our Commitment

Whether for prototype development, design validation, or production at various scales, Huang Liang Precision delivers professional CNC precision machining capabilities and flexible manufacturing systems. We support customers in optimizing processes, improving efficiency, and achieving stable, high-quality manufacturing outcomes—serving as a reliable and trusted machining partner.